Products

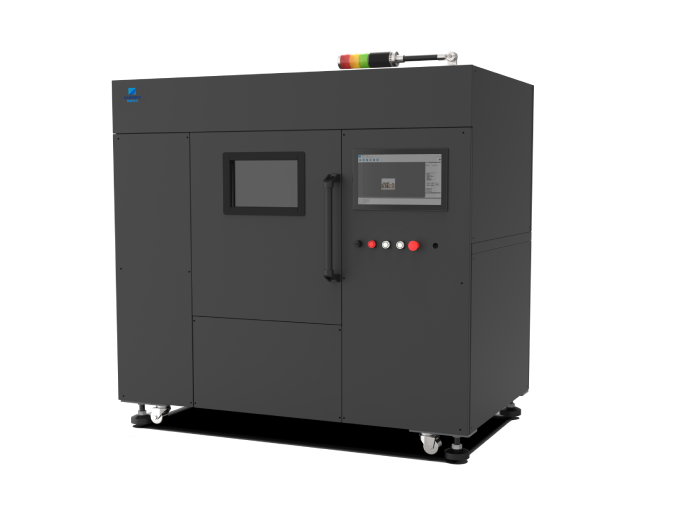

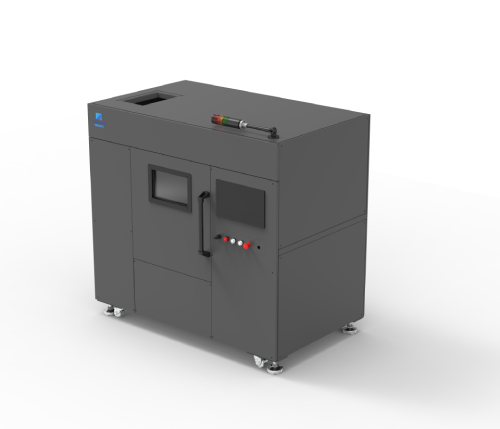

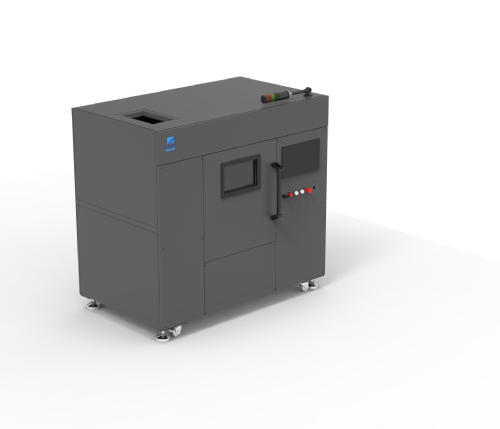

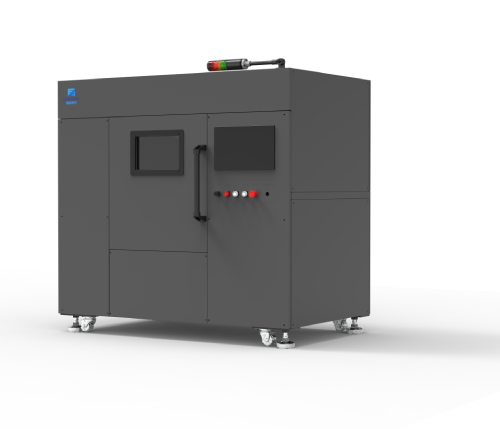

S400lnno

◆ Build Chamber: L 400 × W 220 × H 200 mm (L 15.75 × W8.66 × H 7.87 in)

◆ Build Volume: 17.6 l

◆ Max Build Rate: up to 5.5 l/h

◆ Layer height: Adjustable from 0.2 – 0.5 mm

Product Details

S400Inno: Pioneering Innovation in Material Research and Development

Innovate with Precision:

Elevate your research and development endeavors with the S400Inno, where precision meets innovation. Explore the extraordinary and redefine the boundaries of material research with this cutting-edge 3D printing technology.

Technical Advantages

◆ The waterfall-type powder spreading system is compatible with multiple types of sand

◆ The print head is not prone to clogging and has an auto-clean function

◆ Real-time slicing and RIP algorithms are utilized for for layered manufacturing, allowing for the adjustment of technological parameter

◆ The system has independent intellectual property rights and uses self-developed software

◆ The dosage of binder can be finely tuned

◆ Adaptive nozzle clogging inkjet printing method

|

TECHNICAL SPECIFICATIONS |

|

|

Equipment Model |

S400Inno |

|

Build Box(mm) |

400x220x200 |

|

Precision |

±0.2mm(L<200mm)or ±0.1%(L >200mm) |

|

Tensile Strength |

1-3Mpa |

|

Surface roughness |

Be superior to Ra12.5 |

|

Gas Evolution Rate |

12-20ml/g(850°C) |

|

Printing Speed |

10-30s/per layer |

|

Layer Height(mm) |

0.2-0.5 (Can be adjustable) |

|

Printheads |

One piezoelectric printheads (expandable to 3pcs) |

|

Specification for printheads |

Length=72mm; resolution: 360DPI |

|

File format |

STL、3MF |

|

Electrical Requirements |

Single phase, 220V, 10A, 50HZ |

|

Powder types |

Silica sand, quartz sand, coated sand, etc. |

Resources

Copyright © EASYMFG

Privacy Policy | Terms and Conditions | Inprint