Wei Qingsong:Development and Prospect of Metal Binder Jet Additive Manufacturing Technology

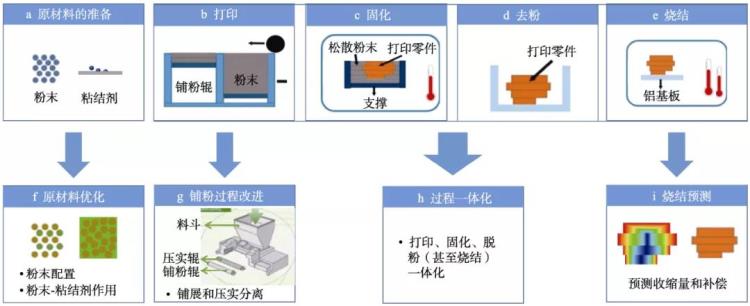

In recent years, metal binder jet additive manufacturing (BJAM) technology has received more and more attention, commercial BJAM printers have been continuously launched, and successful applications have been continuously reported. However, the metal BJAM technology still has shortcomings, and it needs to continue to be optimized in the future. It is summarized according to the BJAM process links, as shown in the figure below.

Binder Jet Additive Manufacturing Metal 3D Printing Process

1. Optimize spreading to improve surface uniformity and density

Powder spreading is very important in the BJAM process, which directly affects the density of the powder bed, which in turn affects the density of the preform and the final part. The influence of powder characteristics and spreading conditions on powder flow behavior is still unclear; compared with high-energy beam melting, BJAM is only a bonding powder, and the height of the powder in the molding area does not decrease, and it will rub against the bonded powder during subsequent powder spreading. Layer, causing uneven spread of the powder and even displacement of the formed layer. To this end, on the one hand, it is necessary to understand and predict the powder spreading behavior in BJAM from the theoretical and methodological basis, and on the other hand, it is necessary to develop a powder spreading mechanism suitable for the BJAM process.

2. The interaction between binder and powder needs in-depth study

The interaction between the binder and the powder particles can significantly affect the geometry, strength, and quality of the final part. The mechanism of binder-powder interaction is not clear. It is necessary to clarify the influence of binder deposition and migration behavior on the quality of the powder bed, and develop a predictive model of the action process.

3. The binder system needs to be rich and perfect

At present, there are relatively few mature adhesives used in metal BJAM technology, and there are also outstanding problems such as easy clogging, low strength, and difficult removal, and most of the adhesives are not suitable for a variety of powder printing. In addition, most of the existing binders are organic, and the residue after degreasing has a significant adverse effect on the performance of the printed parts. Therefore, the development of a new type of adhesive that is suitable for multi-type metal printing, which is resistant to clogging, has high strength, is easy to remove or even does not need to be removed, is very important to promote the progress and application of metal BJAM technology.

4. Prediction and compensation of sintering shrinkage of complex parts

The current model predictions are limited to simple geometric shapes (such as cubes and cylinders). It is necessary to study the shrinkage law and control technology of BJAM printing complex parts, to clarify the sintering deformation mechanism and suppression methods of BJAM printing typical materials, so that BJAM can print complex metal parts. Controllable precision.

5. Process integration

At present, BJAM has many printing procedures, including post-processing such as printing, curing, de-powdering, degreasing, sintering or permeation, which is cumbersome to operate and difficult to control quality. For this reason, it is necessary to study the integration process and equipment of printing and curing, and even realize the simultaneous and intelligentization of printing, degreasing and sintering, simplify the operation process, and lower the process threshold.

Conclusion

In recent years, metal BJAM technology has received great attention due to its high efficiency and low cost advantages. The existing metal BJAM equipment has a maximum molding volume of 800 mm×500 mm×400 mm and a printing speed of 12,000 cm3/h. It has been used in medical, electronics, decoration and industrial fields. The main factors affecting the printing quality of metal BJAM technology include powder characteristics, binder characteristics, printing parameters and post-processing process parameters. At present, the metal materials printed by BJAM include stainless steel, nickel-based superalloys, titanium alloys, copper, etc. The printed Ni 625 alloy has a density of 99.2% and a strength of 718 MPa. The main problems faced by metal BJAM include low density, residual binder and serious shrinkage deformation. Therefore, improving the quality of spreading powder, developing new binders, simulating and predicting sintering shrinkage and process integration are the focus of the future development of metal BJAM technology. direction.

Source: Excerpted from Wei Qingsong's paper "Development and Prospects of Metal Binder Jet Additive Manufacturing Technology"