Metal 3D Printing:A Closer Look at Binder Jetting

Metal additive manufacturing is an innovative and rapidly growing technology that allows engineers to produce complex parts with unparalleled design flexibility. While additive manufacturing was primarily used for rapid prototyping in the past, many additive manufacturing machines can now create robust, reliable final products.

While there are multiple additive manufacturing technologies to choose from, this article will focus on one technology that is best suited for metal mass production - Metal Binder Jetting (MBJ) technology.

What is MBJ?

Metal Binder Jetting (MBJ) is an additive manufacturing process that uses a binder to bond layers of metal powder together. In this process, continuous layers of metal powder are spread on a powder bed, , while the print head moves along the machine's X and Y axes, depositing the binder on the powder bed to build the desired object.

Applications

MBJ has multiple applications, including rapid prototyping and fully functional prototype production. It is also used to create tools, fixtures, and molds quickly and with high precision. The resulting metal parts are dense, durable, and suitable for a range of end products, including aerospace components, molds, hydraulics, and more.

Raw-Finished Interlocking Pipes 3D Printed with Binder Jetting Technology

Source: EASYMFG

Raw-Finished Binder Jet 3D Printed Klein Bottle Beer Opener

Source: EASYMFG

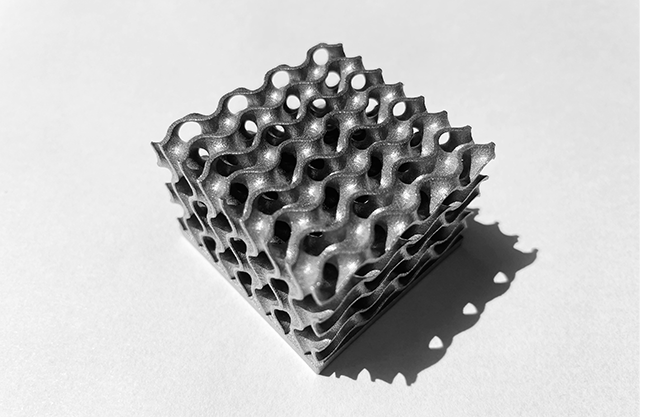

Raw-Finished Lattice Structure 3D Printed with Binder Jetting Technology

Source: EASYMFG

Raw-Finished Valve Plug 3D Printed with Binder Jetting Technology

Source: EASYMFG

Advantages:

Metal Binder Jetting technology has several advantages over other metal manufacturing processes, including additive and subtractive methods. These advantages include:

- Reducing the need for support structures, saving material and post-processing time.

- Up to 99% of loose powder can be recovered and reused during the process.

- Allowing engineers to create complex designs without increasing costs.

- Being able to produce multiple parts in a single print, lowering costs and development time.

- Parts made with binder jetting are isotropic, meaning they have equal strength in all directions.

- Advancements in the technology allow for the production of larger parts and a wider selection of materials.

Binder Jetting metal 3D printing technology has significant cost and efficiency advantages in large-scale metal part production and has received attention from many different kinds of industrial fields!

Compared to traditional metal manufacturing methods, including additive and subtractive methods, Binder Jetting metal 3D printing technology can efficiently recycle and reuse metal powder, making it more environmentally friendly. Additionally, the technology can manufacture complex geometric-shaped parts that are difficult to produce with traditional manufacturing methods. It can also produce multiple parts in a single print, reducing costs and development time.

Due to the high density and durability of parts made with binder jetting metal 3D printing technology, it is suitable for various end-use products, such as aerospace components, tools and molds, hydraulic systems, and more.

As technology continues to advance, the capabilities of metal binder jetting 3D printing technology are also constantly improving. For example, EasyMFG?is researching and developing a wider range of material options as well as higher-precision printing processes and software. These efforts make the technology more suitable for various applications and provide engineers with greater design freedom and innovation space.

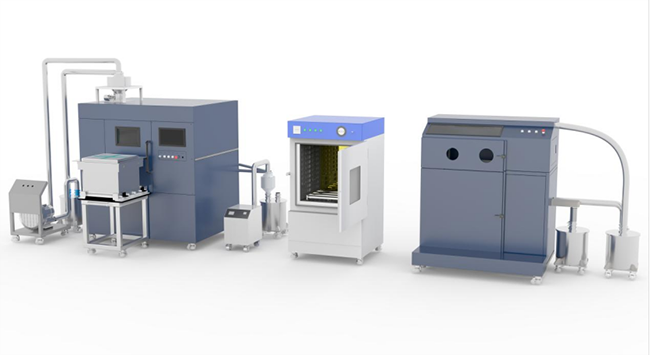

Third Generation MBJ from EASYMFG

The metal binder jetting 3D printing technology developed by EASYMFG has many advantages. For example, it allows for the combination of multiple print heads, with a physical resolution of 600DPI and the ability to customize a print system with a resolution of up to 1200DPI. The technology uses "ONE PASS" printing, with a maximum printing speed of 10 seconds per layer. With its proprietary resin materials, the technology does not require a separate degreasing process and can achieve a density of up to 99% with a single sintering process. It can also support a variety of metal materials, including iron, stainless steel, mold steel, copper, and titanium alloys.

Overall, metal binder jetting 3D printing technology is an innovative manufacturing technique that provides unparalleled design flexibility for engineers, making it an ideal choice for producing metal parts that can be mass-produced with ease.