Revolutionizing the Auto Industry: The Impact of 3D Printing on Directly Printing Auto Parts

3D printing can be said to be a revolutionary technological development. With the continuous development of technology, it is applied in more and more fields. Among them, the use of 3D printing technology to directly print auto parts is a major breakthrough in the auto industry.

Compared with CNC machining in traditional manufacturing, 3D printing has many advantages. For example, 3D printing technology can save many costs in the research and development of vehicle parts, greatly shorten R&D cycle, and improve production efficiency. Then 3D printing is in today's automobile industry. Among them, what are the applications and advantages?

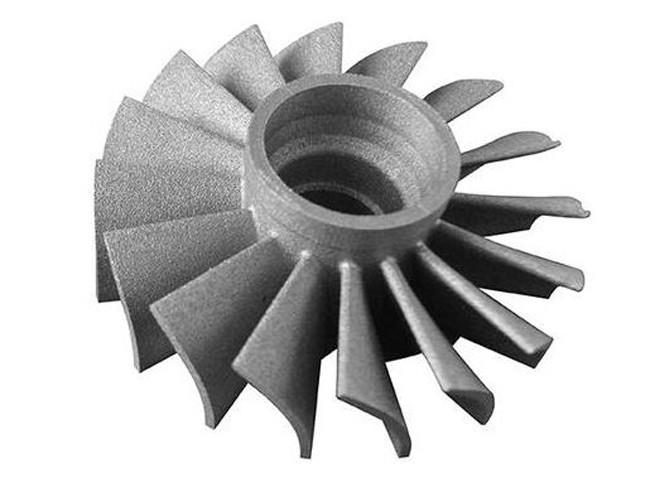

Stator wheel printed by M500

● In terms of auto parts design

Due to the rapid prototyping characteristics of 3D printing, R&D personnel can use 3D printing technology to create a conceptual model on a computer within a few hours or days, and then directly convert the 3D design drawing into a real object, reducing the number of mold openings in the development of complex parts. The link also has higher precision, which results in lower vehicle design and manufacturing costs, shorter research and development cycles, and higher production efficiency.

● In terms of raw material selection

3D printing allows a variety of material choices, different mechanical properties, and precise functional prototype production, enabling designers to correct errors and improve the design at any time in the early stage, and avoid corresponding errors as soon as possible. Error avoidance and richer functional experiments achieved through 3D printing speed up the production efficiency of parts at the design level, and save the manpower and material costs consumed by errors in R&D and design.

● In creating products to meet customer needs

For the current automotive industry, innovation can make products continue to meet market needs. The processing accuracy and achievable complexity of 3D printing are far higher than traditional CNC machining, which can make it more complex, more designable and subversive. Traditional part design can be realized. The more parts that cannot be processed by traditional processing technology, the more 3D printing can be used. For example, wheels with more complex shapes; body skin parts or interior parts with more complicated surface lines and textures; car hollow seats with light weight, safety and comfort, etc., all inspire people to car design New thinking.